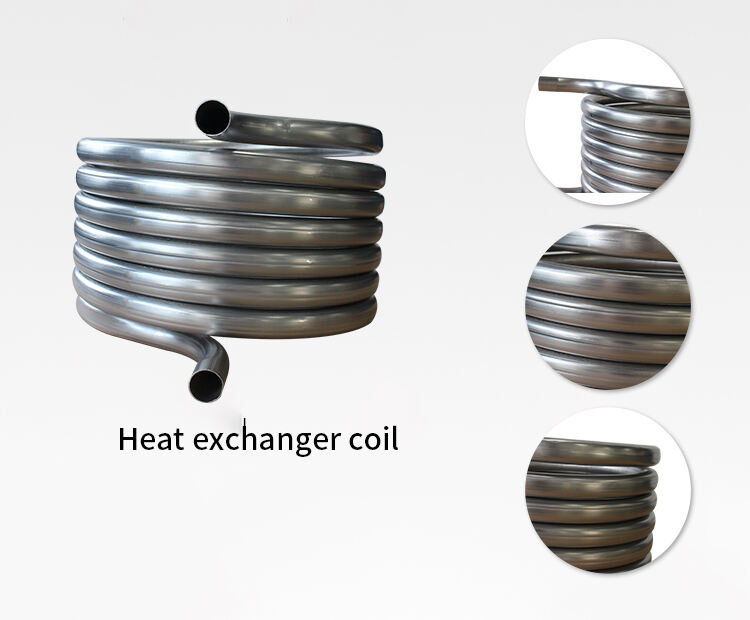

SST helical heat exchanger coil design,titanium coil heat exchanger

| Capacity | L | 100 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 |

| Inner tank diameter | mm | Φ370 | Φ470 | Φ500 | Φ550 | Φ600 | Φ650 | Φ700 | Φ800 |

| Out shell diameter | mm | Φ470 | Φ560 | Φ600 | Φ650 | Φ700 | Φ760 | Φ800 | Φ900 |

| Inner tank material | mm | SUS304 / SUS316L / Duplex2205 / Duplex2304 | |||||||

| Out shell material | mm | galvanized steel with painting / stainless stell / PU | |||||||

| Out shell color | white / silver-grey / blue /red / golden / stainless stell | ||||||||

| Max.working pressure | bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Max.testing pressure | bar | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Max.running temperature | ℃ | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Heating loss | W/K | 0.65 | 0.72 | 0.89 | 1.02 | 1.15 | 1.26 | —— | —— |

| Standing loss | W | 30 | 33 | 40 | 46 | 52 | 57 | —— | —— |

| ERP Class | A | A | A | A | A | A | A | A | |

| Electrical heater | kw | 1.5 | 1.5 | 1.5 | 1.5 | 3 | 3 | 3 | 3 |

| Mg.Anode | mm | Φ22*300 | |||||||

| Water connection | G / BSP / NPT 3/4" | G / BSP / NPT 1" | |||||||

| Packing size | mm |

L:540 W;540 H:117 |

L:630 W:630 H:1440 |

L:670 W:670 H:163 |

L:720 W:720 H:1920 |

L:780 W:780 H:1930 |

L:850 W:850 H:1940 |

Φ900*2200 | Φ980*2420 |

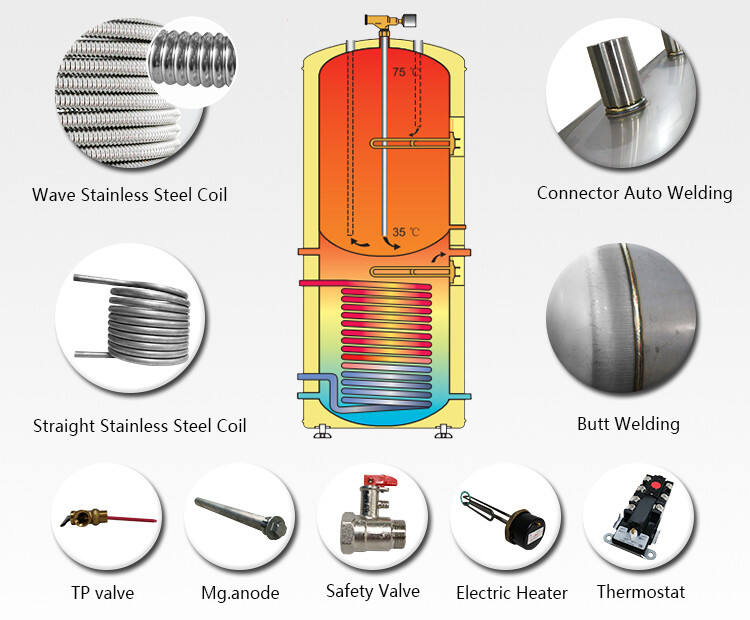

Q1. Material?

For inner tank we have SUS304,SUS316L and Duplex 2205. The most popular is Duplex 2205. For the outer shell is galvanize with painting and stainless steel both are available.Also for the big tank we can do the PU coat.

Q2.Volume?

For now we can do from 20L to 1000L.

Q3. Lead time?

For the LCL order is 15 days after received the payment . for the container order is 25 days after received the advance payment.

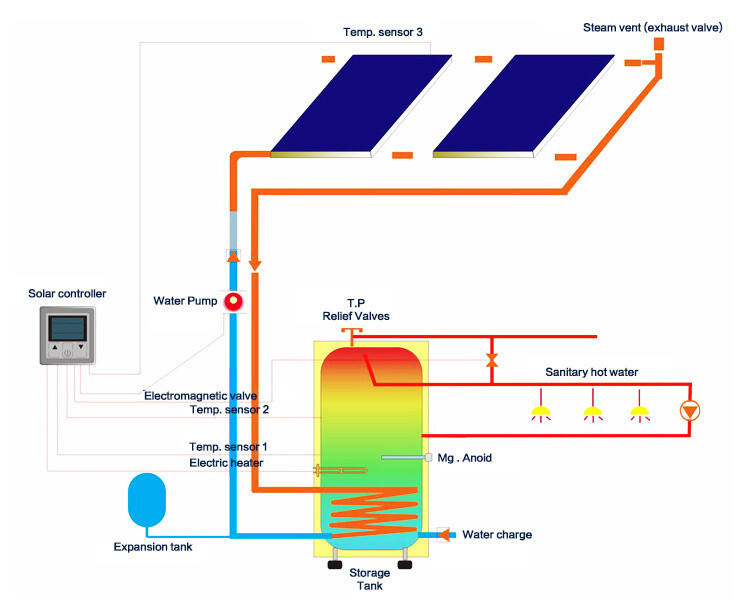

The SST Helical Heat Exchanger Coil Design is really a item is top-of-the-line is designed to satisfy all your heat transfers requirements. Made with high-quality materials and crafted with accuracy engineering, this system is guaranteed to boost the performances and effectiveness of your heat transfers systems.

The titanium coil heat exchanger is one for the key features of this products, supplying exemplary conductivity is thermal durability. The titanium construction makes the warmth exchanger resistant to corrosions, this means it can withstand even the operating conditions that are harshest. Perfect for used in a variety of industrial applications, including chemical processing, oil and gas productions, and manufacturing is pharmaceutical.

One associated with the main benefits associated is its highly designs is efficient. The helical designs of the coils maximize the surfaces area associated with the temperatures transfer areas, leading to improved heat transfers prices and increased efficiency is thermal. This equals lower energy expenses and improved equipment’s performance is general.

Also, incredibly simple to maintains and clean. The coil designs provide access is simple the interiors for the temperatures exchanger, allowing for quick and hassle-free cleaning and maintenance. This ensures that your equipment’s remains in top conditions is working reducing the chances of downtime and fix expenses.

Regarding quality, the SST brands is synonymous with excellence. Every item is manufactured to the highest criteria’s, ensuring that a item is gotten by you is built to last. SST’s commitments to quality and customers satisfaction sets it apart from other brands and makes it the choices is recommended of into the industry.

The SST Helical Heat Exchanger Coil Design with its titanium construction, helical designs, and simplicity of maintenance, is the perfect solutions for many your heat transfer requirements. The SST Helical Heat Exchanger Coil Design is an ideal choice whether you’re looking to improve the efficiency of your industrial processes or reduced operating costs. So why wait? Today Invests in the most useful and experience the difference for yourself.